Plastic Granule Automatic Mixer Gravimetric Blender for 4 Ingredients

Overview Plastic Granule Automatic Mixer Gravimetric Blender for 4 Ingredients Product Description Gravimetric Blender T

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | XGB-200-4 |

| Mixing Barrel Volume | 10 L |

| Power | 0.25 Kw |

| Additive Hopper Volume | 12 L |

| Main Material Mixing Range | 5-100% |

| Additive Mixing Range | 0.5-10% |

| Mixing Capacity | 200kg/Hr |

| Qty of Group Number | 4 |

| Transport Package | Wooden Case as Usual |

| Specification | 280x530x415x150x150 mm |

| Trademark | XIECHENG |

| Origin | China |

Product Description

Plastic Granule Automatic Mixer Gravimetric Blender for 4 Ingredients

Product Description

Gravimetric Blender

The Gravimetric Blenders of Xiecheng are used in injection, extrusion and blowing production with more than one materials by different proportional mixture.

Product Specifications

| Model | XGB-100 | XGB-200 | XGB-400 | XGB-600 |

| Qty of Group Number | 4 | 4 | 4 | 4 |

| Mixing capacity(kg/hr) | 100 | 200 | 400 | 600 |

| Batch weight (kg) | 3 | 3.5 | 8 | 10 |

| Main material mixing range (%) | 5~100 | 5~100 | 5~100 | 5~100 |

| Additive mixing range (%) | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 |

| Main hopper volume (L) | 25 | 32 | 45 | 70 |

| Additive hopper volume (L) | 8 | 12 | 15 | 18 |

| Mixing tank volume (L) | 10 | 10 | 18 | 25 |

| power supply (V/Hz) | 1Φ 230/50 | 1Φ 230/50 | 3Φ 400/50 | 3Φ 400/50 |

| Total power (kw) | 0.12 | 0.25 | 0.55 | 0.55 |

| Compressed air (kgf/cm2) | 6~8 | 6~8 | 6~8 | 6~8 |

| Max. noise level (dB) | <75<> | <75<> | <75<> | <75<> |

| H(mm) | 1725 | 1745 | 1905 | 1905 |

| W(mm) | 925 | 825 | 940 | 940 |

| D(mm) | 700 | 750 | 910 | 910 |

| Base (mm)(HxWxDxBxAxC) | 200*375*275*150*150-Φ100 | 280*535*415*150*150-Φ100 | 280*535*415*150*150-Φ100 | 280*535*415*150*150-Φ100 |

| Mobile tripod (mm)(H1xH2xWxD) | 660*675*560 | 660*675*560 | 800*850*780*610 | 800*850*780*610 |

| Net weight (kg)(machine installation) | 90 | 130 | 140 | 180 |

| Net weight (kg)(floor installation) | 110 | 155 | 165 | 230 |

If you want more sizes, please contact us for details

CONTACT SUPPLIER

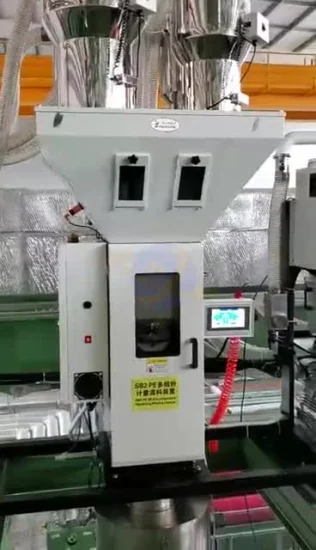

Product Actual Shooting

Product Details

01 PLC Controller

▪ Using PLC controller, the control accuracy is higher, more stable, and easy to maintain;▪ The standard model can handle 4 components, models with more than 6 components can be customized;▪ Color graphic display, touch screen operation, multiple languages for selection;▪ With formula saving function for more than 100 formulas;▪ Classified security password control and alarm history record function;▪ USB2.0 interface for saving recipe data to flash disk, facilitate the quality management.

02 Gravimetric Sensor

▪ Adopt advanced control algorithm, self-optimization, automatic adjustment compensation and vibration prevention functions to ensure the best batching accuracy.▪ High precision: the ratio error can be controlled within 0.3% -0.5%.

03 Metering Valve

Adopt Side-pull metering valve, and the material ratio is less than 5%. The screw metering valve is used, the blanking accuracy is more accurate, the maintenance is simple, and the replacement is convenient.

04 Paddle

All raw material contact parts are made by stainless steel, prevent the materials being polluted.

05 Siemens Electric

Using the world famous brand Siemens electrical components, the performance is stable.

Working Principle

Machine starts working and dosing valve opens to release material by setting values.If controller detects the discharging quantity reached setting value, dosing valve closes up.If discharging quantity stays within allowed error range, machine will discharge next material. When all the material dosing completes, scale valve opens to release materials into the mixing tank. Mixer motor starts to mix. Mixing time can be settled by controller. Mixture will be discharged to the storage tank and ready for injection.

About Us

Company ProfileIn 2009, founded by Mr. Fuzhibo with its head quarter in Jiangmen city which known as a famous hometown of many overseas Chinese, Jiangmen Xiecheng Machinery Co., Ltd. has been devoted herself to be an integrated enterprise of R&D, manufacturing and marketing businesses for High-end Industrial Refrigeration Equipment, Rubber and Plastic Moulding Auxiliary Automation Equipment, and also Intelligent Integrated System Solutions. Authenticated by IS09001, XIECHENG also successfully established the "6+1+C" full dimensional product service system with her own supply chain advantages of combining the six series of products, as Industrial Refrigeration, Mould Temp. Controlling, Material Conveying, Crushing & Recycling, Dehumidifying & Drying, and also Mixing, into central intelligent system solutions as Material Feeding, Air Supply, Water Supply and Power Supply, to fast fitting customers' specific demands.

Exhibition

Related Products

-

![Abrasion Resistant Powder Steel PVC Curve Belt Conveyor System for Transport Granules]()

Abrasion Resistant Powder Steel PVC Curve Belt Conveyor System for Transport Granules

-

![Rotary Air Lock Valve Used in Industry Sawdust Rotary Feeder]()

Rotary Air Lock Valve Used in Industry Sawdust Rotary Feeder

-

![Fully Automatic Gravimetric Doser Blender Weigh Scale Gravimetric Batch Blender]()

Fully Automatic Gravimetric Doser Blender Weigh Scale Gravimetric Batch Blender

-

![High Speed Stainless Steel Mixer Machine Automatic Feeding Gravimetric Color Mixer]()

High Speed Stainless Steel Mixer Machine Automatic Feeding Gravimetric Color Mixer