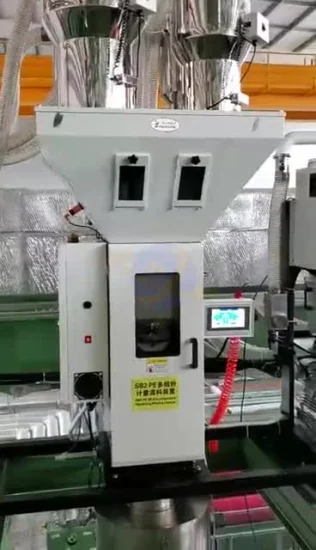

Twin Screw Side Feeder for Plastic Extruder Made by Joiner

Twin Screw Side Feeder for Plastic Powder Coating and Rubber MachineTechnical Specification Simple Graph of CWJ58 Side F

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | side feeder |

| Motor Power(kw) | 1~10 |

| Installation Slope | 0 |

| Chute size(mm) | 3800×960 |

| Overall Dimension | 3920×1640×1320 |

| Transport Package | 1PC/Carton |

| Trademark | JOINER |

| Origin | Sichuan |

| Production Capacity | 200PCS/Year |

Product Description

Twin Screw Side Feeder for Plastic Powder Coating and Rubber MachineTechnical Specification| Screw Diameter(mm) | 58.5mm |

|

| L/D | 8.5:1 | |

| Powder (kw) | 4-5.5kw | |

| Sections of Barrel | 2 | |

| Output Screw Speed | 307 | |

| Feed Materials | fillers, fiberglass, talcum powder, calcium carbonate and most inorganic materials | |

| Load Capacity(kg/h) | 300kg/h | |

| Screw Design: | Double-Screw | |

| Application Machine: | Twin Screw Extruder | |

| Certification: | ISO9001 | |

| Automatic Grad: | Automatic | |

| Side Feeder Consist | the screw ,Gearbox ,Spline Housing, Box, Hopper and Bracket | |

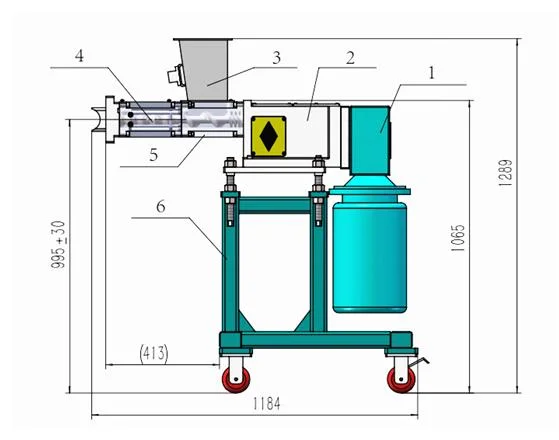

Simple Graph of CWJ58 Side Feeder

| |||

| Mark | Part Name | Qty(Pcs) | Function |

| 1 | SEW Motor | 1 | Driving System |

| 2 | Gearbox Section | 1 | Transmission System |

| 3 | Hopper | 1 | Feeding |

| 4 | Screw Section | 2 | Mixing and Conyeying the Filler |

| 5 | Barrel Section | 2 | Carry the Screw Shaft and Melt the Material |

| 6 | Bracket | 2 | Supporting the Side Feeder |

Advantage of Joiner Extrusion Side Feeder

1.Independently develop and produce gearboxes.

1)All gearboxes are machined by gear grinding, the accuracy is up to six grades, and carburizing and hardening the tooth surface, thus ensuring that the noise of gearboxes is very low.

2)gear casting is made of resin sand and machining center to ensure high precision.

3) the gearbox's bearing is imported from Germany.

4)the gearbox has unique design, long life and low noise.

5)the gearbox and screw element are connected by spline sleeve, which is easy to disassemble and clean, and is very convenient.

2. barrel is made of wear resistant alloy steel and cooled by water channel.

3. screw adopts modular screw, and the screw assembly can be adjusted according to different feeding materials to meet different feeding requirements.

|

|

Our strengths are based on many years experience supplying the following:

* Competitive costs per unit of production

* Fast turn round for collection and delivery on refurbished parts

* Parts available from stock for a wide range of extruder makes

* Comprehensive inspection procedure on all parts prior to dis

* A time proven quality service

* Latest manufacturing techniques and metallurgy, ensuring consistent and reliable performance of parts

* Customized solutions to meet specific needs

Product Information

The forced side feeder is designed to match with twin-screw extruder, to provide optimum feeding properties for a wide range of raw materials such as fillers, fiberglass, talcum powder, calcium carbonate and most inorganic materials during the twin-screw extrusion production.

Its working principle is that the materials are feed by the quantitative feeder then trough the forced side feeder, which pass through the special the barrels and intermesh segment screw to the extruder.

The features of our side feeder

Our late model side feeder adopts the integral wear resistant steel sleeve in the barrels, used for glass fiber filler, it improve the abrasion resistance to prolong the service life. for the screw, instead of the integral type with equal screw pitch, we put the intermeshing segments with equal gap, a variety of pitch, modular assembly through the shaft. It improve the force conveying effect to ensure the accuracy and the output.

We also adopt some humanistic structures on the side feeder, such as

the glass window, on the splined sleeve, flat screw head the adjustable support and the drawer for clean up the leak ,which enables users more convenient. For some special user requirements, we also can design.

Human design, the overall steel replaceable wear sleeve, easy to clean.

Applies to the melting point of different polymers, polymers with very different bonding degree, liquid polymers, thermosensitive polymers and additives for mixing processes.

Our Production Plant

Our Production Line

Vacvum Quencher

Testing Machinery

Testing Machinery

Quality control ability

JOINER have lots of high-precision machining and testing equipments: automatic lathes, CNC lathes, CNC millers, digital millers,laser marking machines,wire cut and other processing machines. Joiner also has a professional technician team.JOINER has established an effective quality controlling system, in which all staff members are involved. Besides, it has a well-trained quality controlling team, a professional quality engineering team and fine testing equipments as well,which provides scientific and thorough testing and inspection. In quality planning and management, we strictly follow the ISO9000.

FRQ

1. Q: Are you a factory or trading company?

----A: A factory

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Chengdu, Sichuan Province, China,

1) You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport;

All our clients, from domestic or abroad, are warmly welcome to visit us!

3

Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 028 87226313, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

4

Q: How about the delivery time?

----A: This depends on the product. Typically standard products are delivered within 30 days.

5

Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.